Innovation Award EnergyDecentral 2024

EnergyDecentral, the international trade fair for decentralized energy supply, has established itself as the most prominent platform for the introduction of innovations. This innovation leadership is underlined by the EnergyDecentral Innovation Award, which is handed to the winners at the show every two years.

An independent expert committee appointed by the DLG (German Agricultural Society) has selected the EnergyDecentral 2024 Innovation Award winners resulting in two gold and one silver medals.

The winner of the Innovation Award EnergyDecentral in gold are:

Kramer-Werke GmbH in cooperation with: Bosch Rexroth AG

Telehandler KT316 with integrated dynamic weighing system

Hall 27, Stand C15

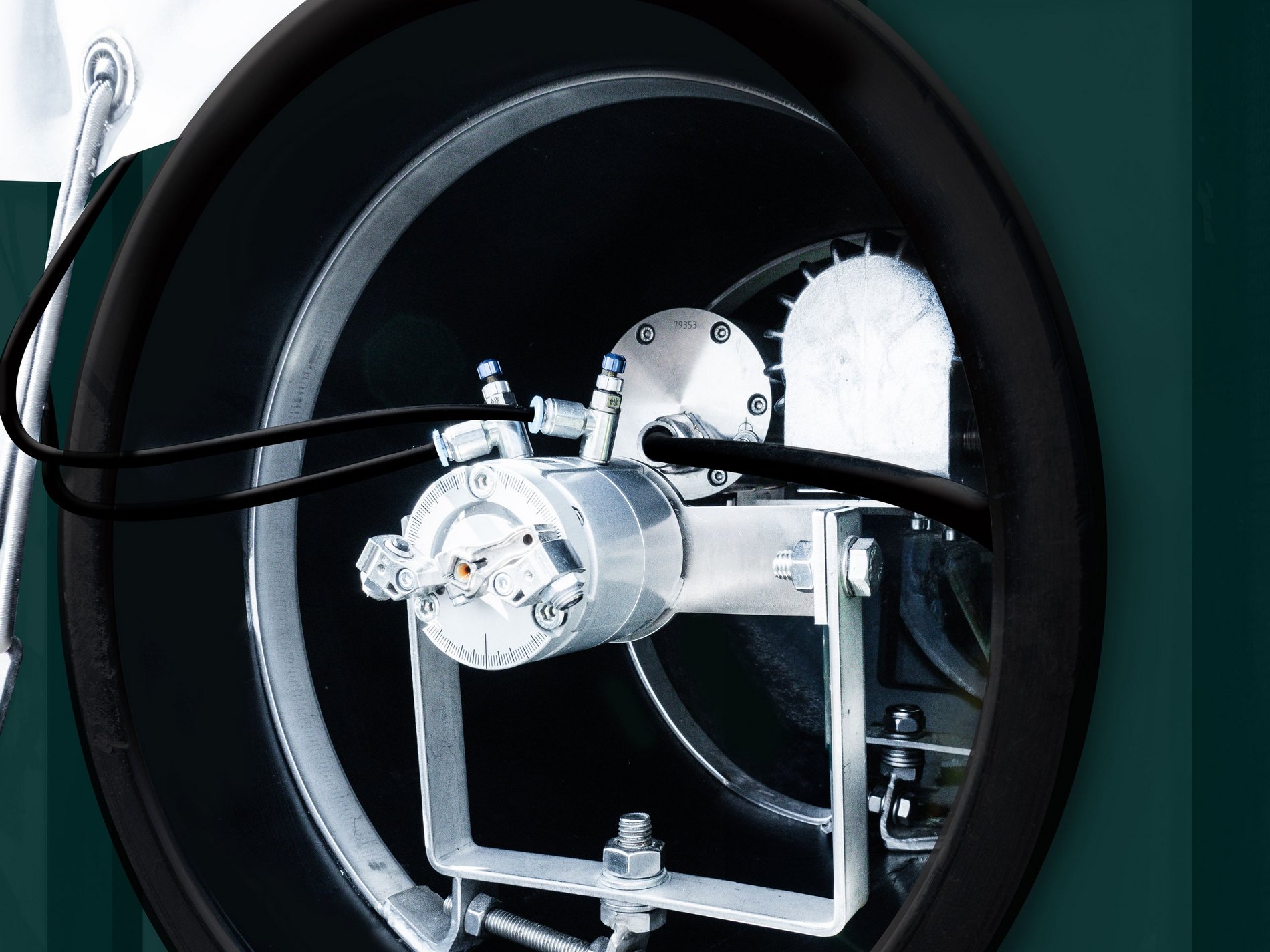

The integrated dynamic weighing system for telehandlers from Kramer extensively simplifies shovel weighing and improves its accuracy, whereby the possibility of carrying out the weighing process even during operation leads to only a slight loss of time.

While weighing systems for loaders are widespread, they have so far proved to have crucial disadvantages, because they do not operate dynamically. This means that the load centre of gravity of the respective implement has to be taken into consideration and calibrated. Successful weighing also entails stopping on a flat surface and running through a defined lifting range. Added to this is the fact that only retrofit solutions have so far been available for telehandlers.

In this respect, the telehandler KT316 with integrated dynamic weighing system from Kramer is a fundamental new development that integrates a dynamic weighing system into a telescopic loading system for the first time. This is particularly helpful and of high practical relevance for biogas plants, as the effort required to document the substrates that are used in compliance with the law is particularly high. Shovel weighing can be carried out much more easily in the future, whereby the reduced loss of time thanks to the weighing process, even during operation, and the accuracy of the system were particularly praised by the jury.

The innovative character of the dynamic weighing system consists of the fact that it operates independently of the implement, the load centre of gravity or the position of the loading system including the telescoping function.

PlanET Biogastechnik GmbH

PlanET KI camera system

Hall 25, Stand G14

The AI camera system from PlanET Biogastechnik GmbH equates to a quantum leap in controlling the agitation process in biogas plants, because it enables automatic monitoring and data-based control for the first time.

To date, biogas plant agitators are adjusted manually and via a sight glass depending on a visual inspection carried out by the operator. This manual adjustment of agitation times, rotational speeds or agitator positions is extensively dependent on the operator's feel and experience, and runs the risk of major disturbances, particularly if these arise shortly after a visual inspection.

Initial concepts for automated monitoring and control of the agitation process have already been in existence for some time. The AI camera sytem from PlanET Biogastechnik continuously monitors the agitation quality, foam formation and floating layer formation for the first time, assesses the conditions in the tank by means of AI-aided image evaluation and implements corresponding control measures based on the available data without the operator having to intervene. This equates to a quantum leap for the agitation process, particularly as this improved agitator control will also enable the energy used for the agitation process to be optimised in the future. The system is supported by an automatic wiping, cleaning and lighting system which enables a clear view under all circumstances.

As well as being technically highly innovative due to its AI approach, the AI camera from PlanET Biogastechnik marks the presentation of a system for automatic, needs-based agitation in biogas plants for the very first time.

The winner of the Innovation Award EnergyDecentral in silver is:

agriportance GmbH

agriportance Software

Hall 25, Stand K27

The agriportance software simplifies the preparation of greenhouse gas and mass balances and offers the option of training users and employees, which enables the process to be extensively simplified and internal costs to be reduced as well as saving resources and cutting CO2 emissions.

So far, the data for preparing a greenhouse gas (GHG) or mass balance at companies subject to mandatory reporting has been recorded manually in tables and transferred by post or e-mail to a service provider, which then calculates the balance. Customers are rarely able to access and adjust their data directly or to establish a progression.

The agriportance software remedies this by significantly simplifying recording and calculation when balancing greenhouse gases or masses. In particular, data in various formats can be automatically imported and the corresponding balances prepared quickly and easily with the aid of advanced algorithms. The best possible value is always found by comparing standard and individual values and can be used for an optimum result. Changed statutory regulations or calculation bases are continuously integrated by the app manufacturer, with the result that the app is constantly up to date. Training courses for sustainability certification are also offered.

This significantly reduces the workload at companies subject to mandatory reporting and enables strategic corporate development with respect to GHG and mass balancing.

The agriportance software therefore constitutes a significant evolution of the existing GHG and mass balancing process.